Make sure foundation cracks are fixed correctly!

There’s a “Right Way” and a “Wrong Way” to repair cracks.

Here’s the wrong way:

“Crack Repair” sounds simple but unfortunately, many contractors take the simple approach. The common method is to simply fill in the crack with fillers, sanding and finishing off the surface and then painting over it. This method will repair the crack cosmetically, but it doesn’t address the underlying causes of the crack nor stop the crack from continuing to grow in the future. Amazingly, the injectors are frequently left behind. They look like small caulking tubes and they get sealed into the repair. The crack is then finished off with surface concrete and painted over and it typically looks like this:

This type of repair is a band-aid, nothing more. You might get lucky and the crack will not continue to grow, but if your home settles, or perhaps the water table beneath your house shifts, the crack can, and often does, return. And when it does, the problem is compounded because not only does the original repair need to be corrected, but the additional crack growth needs to be repaired as well. All of this can be avoided if the crack is repaired properly.

The Right Way To Repair Cracks:

DryMaster Basement Waterproofing utilizes “Carbon Fiber Reinforced Polymer” (CFRP), a patented crack repair system utilizing carbon fiber and structural polymers to create a repair that is far stronger, far more effective, less costly and can be installed in about half the time – and with fewer tools – than other competitive repair methods.

This type of repair is 10 times stronger than steel. It’s extremely effective for both residential and commercial applications. It involves a significant amount of both surface and below surface preparation. The crack is fully exposed; any previous inadequate repairs are removed. The crack is then completely filled with carbon fiber inserts from one end to the other. Next, we utilize our own polymer blend to permanently bond the carbon fiber with the concrete in your foundation. The surface is also finished off with carbon fiber matting which is also bonded to the foundation. Only then is the surface sealed and painted:

High-performance sports and race cars, along with modern military and passenger aircraft, are built using these same techniques. The combination of carbon fiber and polymers is simply one of the strongest construction methods ever created and it is still considered to be cutting-edge. The proof is in the pudding! Utilizing this method, DryMaster Basement Waterproofing has achieved a 100% track record of success. In our 20+ years of business, we have never had to go back to a job for any type of warranty repair.

Residential Applications:

For cracks in your footer or foundation, walls or floor, DryMaster Basement Waterproofing uses “Carbon Fiber Reinforced Polymer” (CFRP), a patented crack repair system utilizing carbon fiber, and structural epoxy to create a repair that is far stronger, far more effective, less costly and can be installed in about half the time – and with fewer tools – than other competitive repair methods.

Once a crack develops, moisture can spread and erosion begins, weakening the condition of the concrete around the affected area, compromising its structural integrity. Carbon Fiber Reinforced Polymer can be used to remedy the problem or to reinforce a crack repair to provide peace-of-mind that it will not re-open. In addition to the strength properties provided by CFRP, waterproofing capabilities are another benefit to its use.

From garage floors to basements, to foundations and retaining walls, Carbon Fiber Reinforced Polymer (CFRP) has been relied upon for the strengthening of concrete infrastructure under the most extreme conditions. If you have cracks in any part of the concrete in your home, give DryMaster Basement Waterproofing a call today.

Commercial Applications:

Once a crack develops, moisture can get to the reinforcing steel and corrosion begins. As the corrosion progresses it worsens the condition of the concrete around the affected area, compromising the structural integrity of the component. Carbon Fiber Reinforced Polymer can be used to remedy a problem injection or to reinforce a crack repair to provide peace of mind that it will not re-open. In addition to the strength properties of CFRP– it’s ten times stronger than steel – its waterproofing capabilities are another benefit to its use:

Bowed Wall Stabilization:

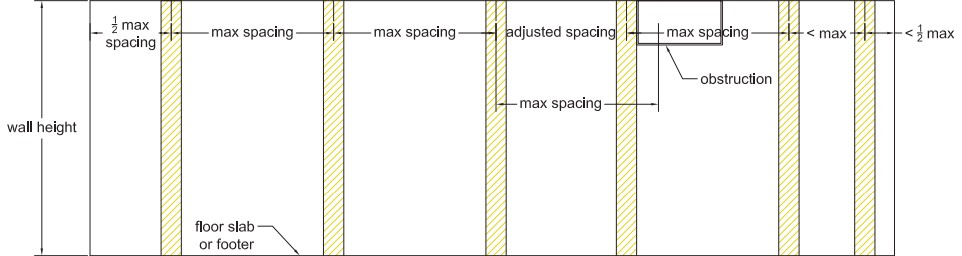

Block or CMU walls fail for several reasons, from lack of reinforcing steel to excessive loads due to expansive soils or excess ground water. Even with the appropriate amounts of reinforcing steel in place, where the walls are constructed properly, expansive clay soils can still cause bowing if the cores are not fully grouted.

The solution is Carbon Fiber Composite Straps that permanently secure and stabilize the basement wall against any further inward movement. The industrial strength adhesive epoxy penetrates deep into the pores of the concrete, while saturating the carbon fiber providing a permanent bond to the foundation.

Stem Wall Foundation Repair:

Foundation stem walls can experience a variety of failures. Often horizontal cracks appear which can be the result of the reinforcing steel being too close to the outer edge of the forms when the foundation was poured. When the forms are stripped, and if the conditions of the steel being hot on the day of the pour, a fine micro crack appears.

The concrete around the steel also begins curing outwards meeting the normal curing of the concrete, curing from the outside towards the middle. These two curing areas form a micro crack. With seismic activity or foundation settlement, the foundation may bend slightly, causing the crack to open, exposing the reinforcing steel to corrosion. Commercial strength carbon fiber, bonded with structural epoxy adhesive (CFRP) forms an advanced composite strengthening system that provides over 35,000 lbs/sq ft of confinement strength over cracks. This application prevents cracks from spreading while reinstating capacity to the wall.